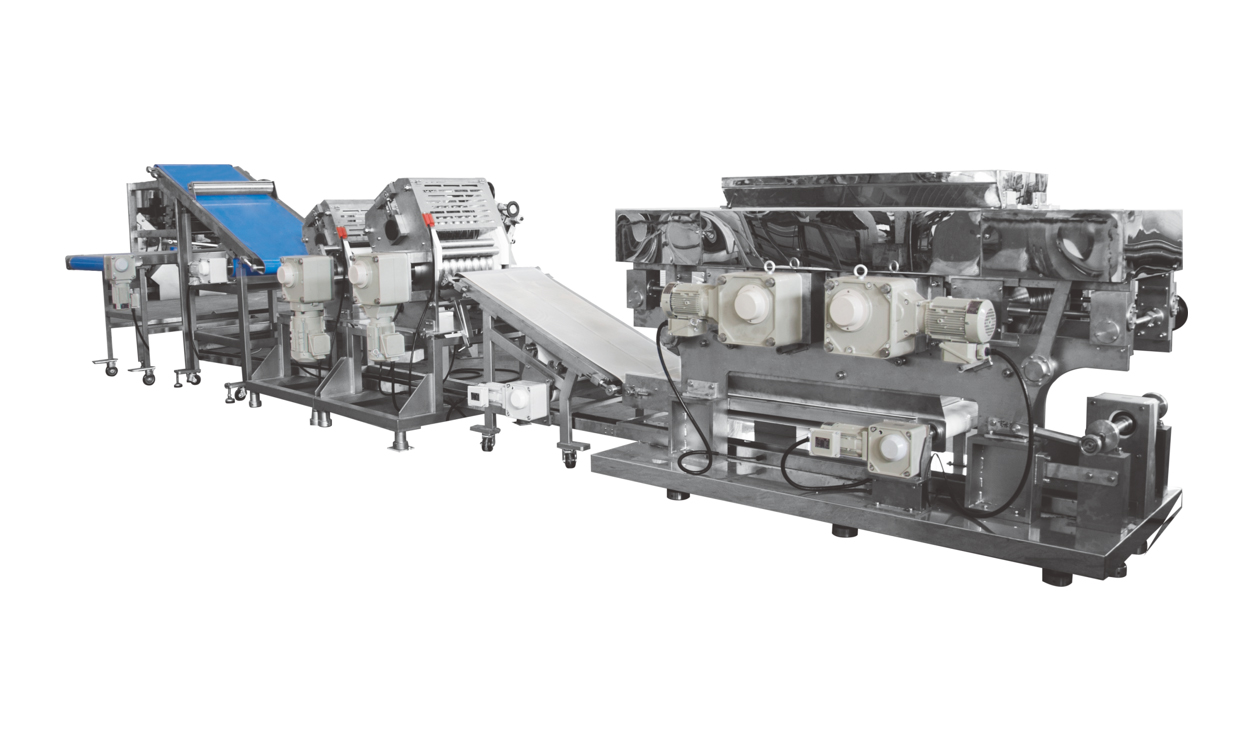

Automatic Ramen Noodle production line with Cooking Machine

Performance & Features

- The entire noodle production line is made of 304 stainless steel to ensure that there will be no food safety problems caused by equipment during noodle production.

- The vacuum dough mixer is used to improve the quality and toughness of the dough, reduce the mixing time, and improve production efficiency. In addition, the vacuum dough mixer adopts a U-shaped box to reduce friction heat during dough mixing, greatly reducing the temperature rise caused by mixing during dough mixing;

5. The automatic powder feeding device of the noodle machine is isolated from the production workshop, reducing the amount of dust in the production workshop, and greatly reducing the problem of excessive microorganisms caused by floating dust and water breeding;

7. The rolling part is all driven by a single machine. The chainless direct connection significantly eliminates the generation of noise. The photoelectric switch adjustment of a single group of rolling machines is linked to each other. There is no need to frequently adjust the gap between the rollers when switching between products of different specifications.

8. In addition to being equipped with different noodle knife types, it can also be equipped with a dumpling wrapper forming machine and a wonton wrapper forming machine, making it a multi-purpose machine.

3. Abandon the traditional layout of raising the dough mixer, and adopt a floor-standing dough mixer to facilitate cleaning of the dough mixer and save manpower.

4. PLC automatically controls automatic water and powder feeding technology, which can control the water feeding error within 3‰.

6. The rod-type hanging noodle belt maturation box and the horizontal flat maturation box can be selected according to the dough process.

Technical Parameters

|

Model |

Power |

Rolling Width |

Productivity |

Dimension |

|

DM-440 |

35-37kw |

440 mm |

500-600 kg/h |

(12~25)*(2.5~6)*(2~3.5) m |

Machine Video

Production Cases