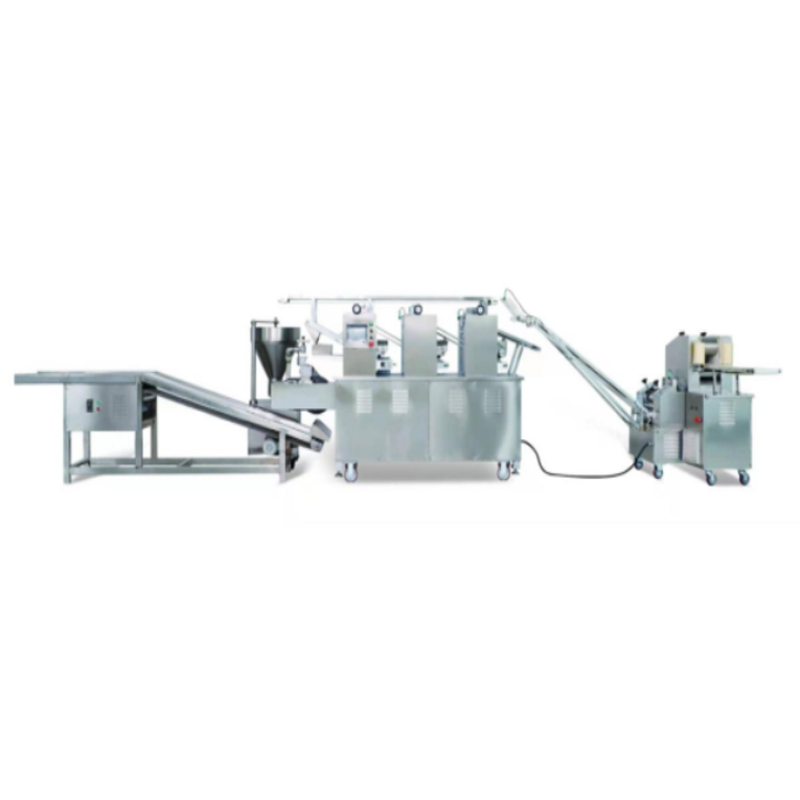

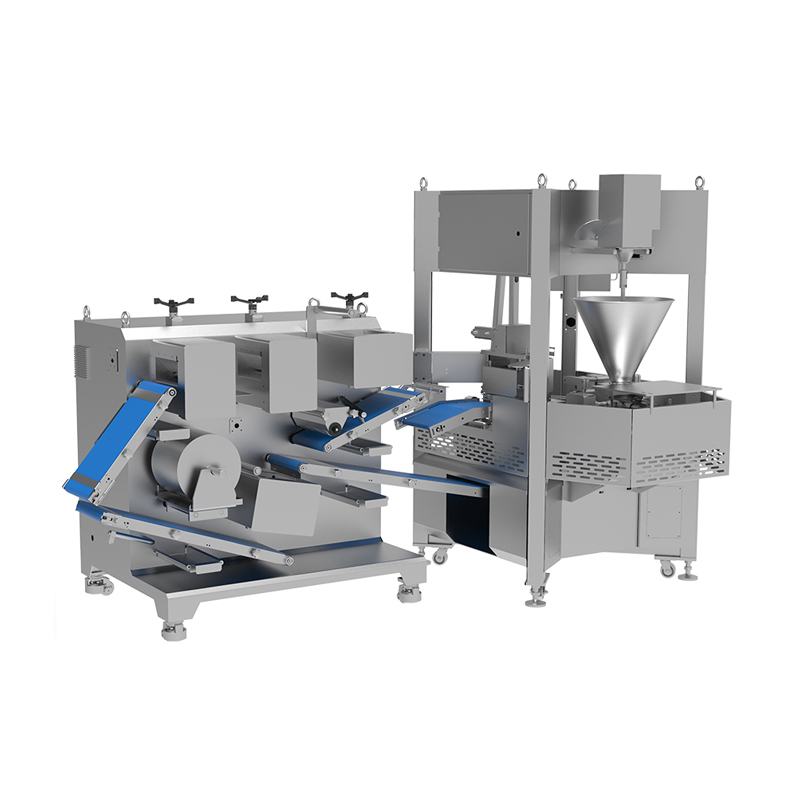

Full Automatic Dumplings /Noodles Steaming Tunnel

Features and Benefits

- Customized the steaming tunnel as the capacity,food type, and production site.

- The Dumpling steaming tunnel is equipped with multi-section temperature sensors, which can monitor the temperature of the steam box in real time.

- The hot steam is evenly distributed inside the steamer. The overall heat distribution temperature difference is ±1.5℃; the heat distribution temperature difference between the top, bottom, left and right of each section is ±1℃;

- Multiple IP65 protection level emergency stop buttons ensure production safety.

- #314/#316 stainless steel conveyor belt is optional, frequency conversion speed regulation, automatic tensioning system.

- Multi-stage high-pressure water pump automatic cleaning device.

- Fully automatic lid lifting device controlled by PLC.

- ,The main inlet of the steam pipeline is equipped with a power-off normally closed valve,Prevent uncontrolled steam from scalding people when the power is off.

- The whole set of equipment adopts PLC control, inverter device, etc. to realize fully automatic intelligent control.

- High-quality electrical components, such as Siemens, Inovance inverters, Schneider, Omron encoders, etc.

Application

HELPER food cooking tunnels will be designed and produced according to the type and output of food. Currently we can provide noodle cooking tunnels,dumpling cooking tunnels、 Pet food steaming tunnel.

Machine Video

Write your message here and send it to us