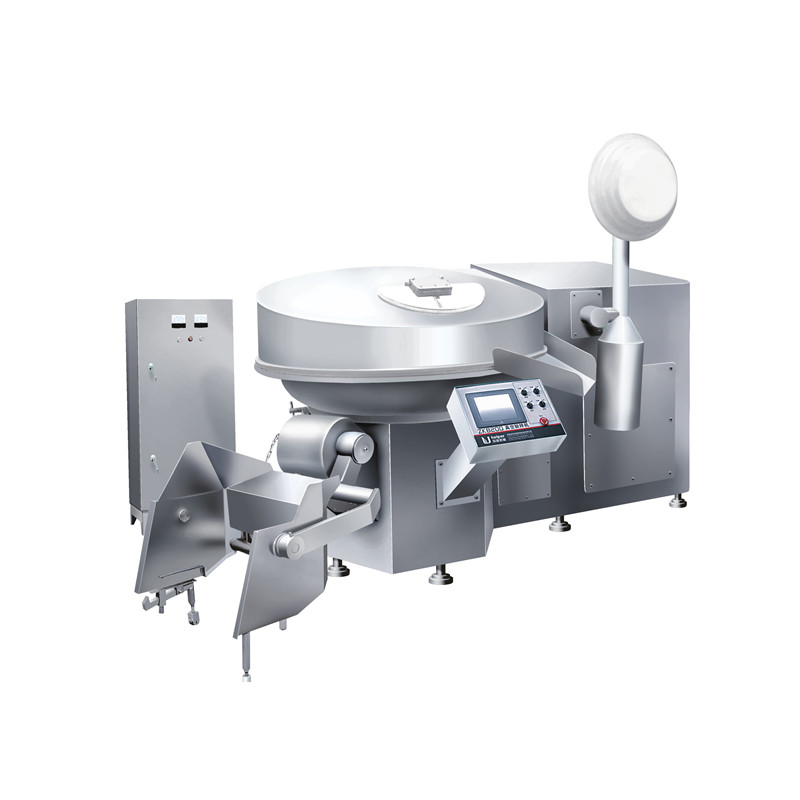

Industrial Vacuum Meat Mixers 2500 L For Meat Food Factory

Product Introduction

It should not be a secret that the mixing process is critical for the quality of the final food product and your overall line productivity. Whether that would be a chicken nugget, a meat burger or a plant-based product, a precise and controlled mixing process at the start will affect the forming, cooking and frying later, and even the product’s shelf performance.

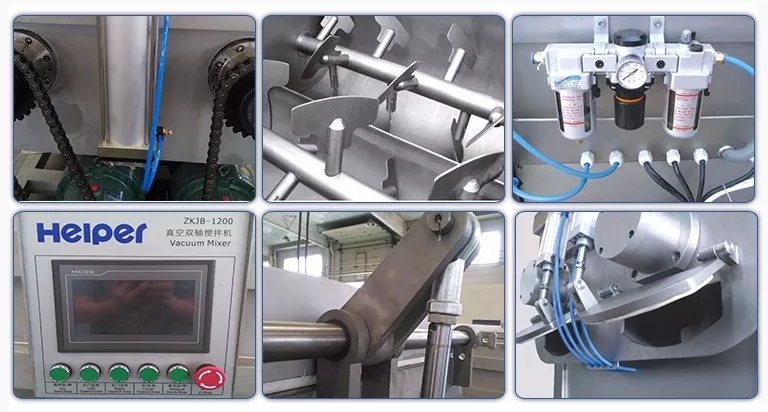

Ideal for fresh and frozen and fresh/frozen mixtures, Independently driven mixing wings provide different mixing actions - clockwise, counterclockwise, inwards, outwards - to aid optimal mixing and protein extraction High peripheral wing speed helps to optimize protein extraction, and ensure uniform distribution of additives and effective protein activation.

Short mixing and discharge time with a design that helps to minimize product residue and so reduce cross mixing of batches.

Features and Benefits

● High-quality SUS 304 super quality stainless steel structure, meeting the standard of food hygrene, easy to clean.

● Dual shaft system with mixing paddles, smooth, variable speed of mixing by using inverter

● Clockwise and anticlockwise rotations

● The cantilever tool structure is convenient for washing and does not damage the motor.

Technical Parameters

|

Vacuum Dual Shaft Mixer |

||||||

|

Type |

Volume |

Max. Input |

Rotations (rpm) |

Power |

Weight |

Dimension |

| ZKJB-60 |

60L |

50 kg |

75/37.5 |

1.5 kw |

260 kg |

1060*600*1220 mm |

| ZKJB-150 |

150 L |

120 kg |

80/40 |

3.5kw |

430 kg |

1360*680*1200 mm |

| ZKJB-300 |

300L |

220kg |

84/42 |

5.9kw |

600 kg |

1190*1010*1447 mm |

| ZKJB-650 |

650L |

500 kg |

84/42 |

10.1kw |

1300 kg |

1553*1300*1568 mm |

| ZKJB-1200 |

1200L |

900kg |

84/42 |

17.2kw |

1760 kg |

2160*1500*2000 mm |

| ZKJB-2000 |

2000L |

1350kg |

10-40 adjustable |

18kw |

3000 kg |

2270*1930*2150 mm |

| ZKJB-2500 |

2500L |

1680 kg |

10-40 adjustable |

25kw |

3300 kg |

2340*2150*2230 mm |

| ZKJB-650 Cooling |

650L |

500 kg |

84/42 |

10.1kw |

1500 kg |

1585*1338*1750 mm |

| ZKJB-1200 Cooling | 1200L | 900kg | 84/42 | 19kw | 1860kg | 1835*1500*1835 mm |

Machine Video

Application

HELPER twin shaft paddle mixers are versatile for a variety of all-meat or extended meat products, fish and vegetarian products, and for pre-mixing wiener and frankfurter emulsions. HELPER Pro Mix mixers gently, effectively, and quickly combine most types of products, regardless of viscosity or stickiness. From stuffing, meat, fish, poultry, fruits, and vegetables to cereal mixes, dairy products, soups, confectionary items, bakery products, and even animal feed, these mixers can mix it all.