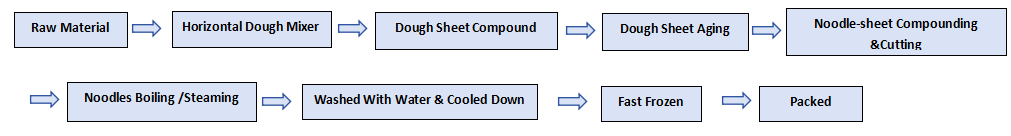

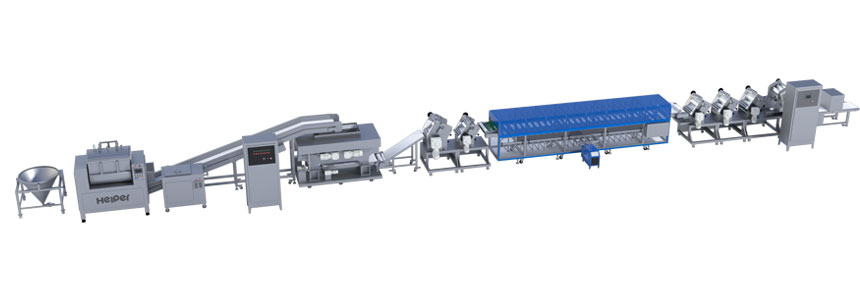

Automatic frozen cooked instant noodle making machine

Equipments

The equipment for producing noodles includes Horizontal Vacuum Dough Mixers, noodle-sheet compounding press rollers, Twill-weaved noodle-sheet press rollers, vacuum dough compound calender, Automatic noodles slitting & cutting machine, Continuous Noodle-sheet Aging Machine, Noodle-string Roll Slitter&cutter, Automatic Noodle Boiling Machine, Continuous Steam Sterilizer, Automatic Noodle Steaming Machine, Metal detector, vertical Packaging Machine, Pillow Packaging Machine etc.

Technical Parameters

|

Model |

Power |

Rolling Width |

Productivity |

Dimension |

|

M-270 |

6kw |

270 mm |

200 kg/h |

3.9*1.1*1.5m |

|

M-440 |

35-37kw |

440 mm |

500-600 kg/h |

(12~25)*(2.5~6)*(2~3.5) m |

|

M-800 |

47-50 kw |

800 mm |

1200kg/h |

(14-29)*(3.5~8)*(2.5~4) m |

Features and Benefits

● Fully Automatic Productio, Enhanced Efficiency: HELPER Noodles making machine is central integrated control system, and the entire production line can be operated by only about 2 people.

● Enhanced Efficiency: By offering complete automation, our machinery significantly reduces production time and labor costs, resulting in higher productivity and ultimately, improved profitability.

● Consistent Quality: With precise control over the production process, our machinery ensures the consistent texture, thickness, and taste of the noodles, meeting the high standards expected by discerning customers.

● Customizable Design: HELPER Noodles Making Machine will customized accommodate various noodle production volumes, manufacturing processes, and factory layouts.

● Versatile Applications: Our machinery is suitable for producing a wide range of noodles, including ramen, udon, soba, and more, allowing you to cater to diverse market demands.

● Easy Operation and Maintenance: Designed with user-friendly interfaces and intuitive controls, our machinery is easy to operate and maintain, even for those without extensive technical knowledge.

Machine Video