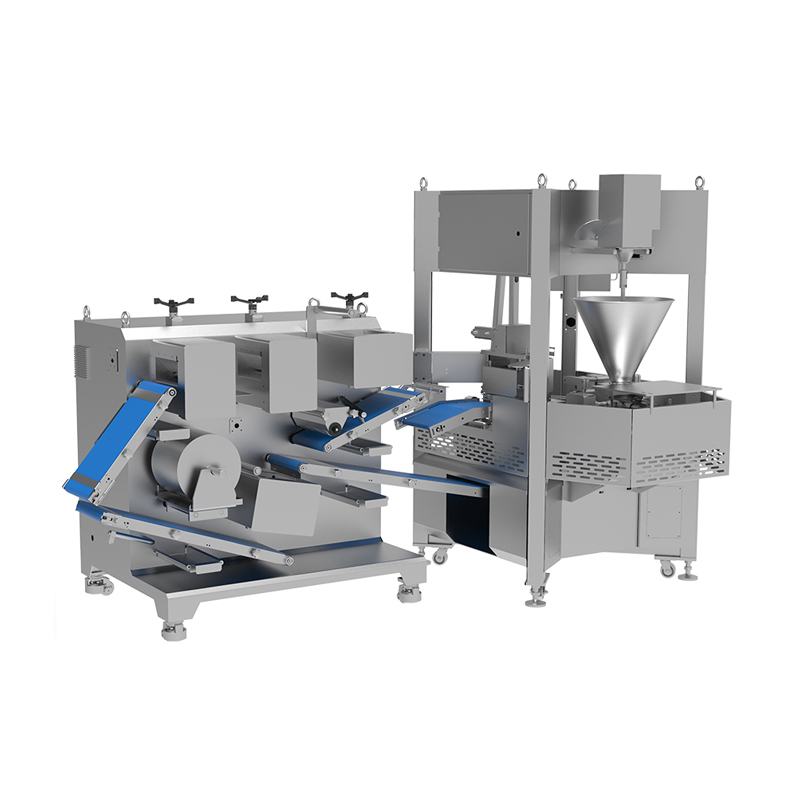

Automatic Asian Noodles Making Machine 200kg Per Hour

Features and Benefits

The vacuum dough mixer mixes dough under vacuum and negative pressure, which allows the wheat flour protein molecules to quickly and fully absorb water. It not only promotes the full formation of the gluten network structure, but also greatly reduces the free water between protein molecules and improves the density of the dough. Significant improvement, so that the soluble content of the prepared noodles is reduced during the cooking process, the soup is not mixed, and the taste is smooth, chewy and elastic when eaten.

The M-270 Continuous Pressing Roll Machine consists of one set of large-diameter rolls and four sets of small rolls. Each roll with separate motor allows adjustment to any noodle pressing speed as required. Sensor detects slack of noodle sheet between rolls, and adjust it automatically. No chain-drive is used to provide a quiet production environment.

Roller vertical structure, both to save space, but also to ensure the dough sheet proper thickness.

The Air Energy Dryer has the characteristics of energy saving, environmental protection, no pollution, low energy consumption, intelligent control of temperature and humidity without manual operation, saving time and effort, not affected by seasons and weather, and continuous and uninterrupted production. The main loss in the drying process is It is moisture, retaining the original flavor, color and nutrition of the material to the greatest extent, so that the finished product after drying has good color and complete nutrition, truly achieving a high degree of automation, closed operation, energy saving and environmental protection, and adapting to a wide range of products. It is Ideal for food drying equipment.

Application