Vacuum Dough Mixer With Cooling Systerm For Bread

Features and Benefits

-- Simulate the principle of manual dough mixing under vacuum and negative pressure, so that the protein in the flour can fully absorb water in the shortest time, and the gluten network can be quickly formed and matured. The draft of the dough is high.

-- High-quality 304 stainless steel structure,Comply with food safety production standards, not easy to corrode, easy to clean.

-- The paddle obtained the national patent, has three functions: Mixing, kneading and aging the dough.

-- Unique sealing structure, easier to replace seals and bearings.

-- PLC control system, the mixing time and vacuum can be set according to the process.

-- Automatic water supply and automatic flour feeder are available

-- Suitable for noodles, dumplings, buns, bread and other pasta factories.

Technical Parameters

| Model | Volume (Liter) |

Vacuum (Mpa) |

Power (kw) |

Mixing Time (min) | Flour (kg) | Axis Speed (Rpm) |

Weight (kg) | Dimension (mm) |

| ZKHM-150V | 150 | -0.08 | 16.8 | 6 | 50 | 30-100 Frequency Adjustable | 1500 | 1370*920*1540 |

| ZKHM-300V | 300 | -0.08 | 26.8 | 6 | 100 | 30-100 Frequency Adjustbale | 2000 | 1800*1200*1600 |

Machine Video

Application

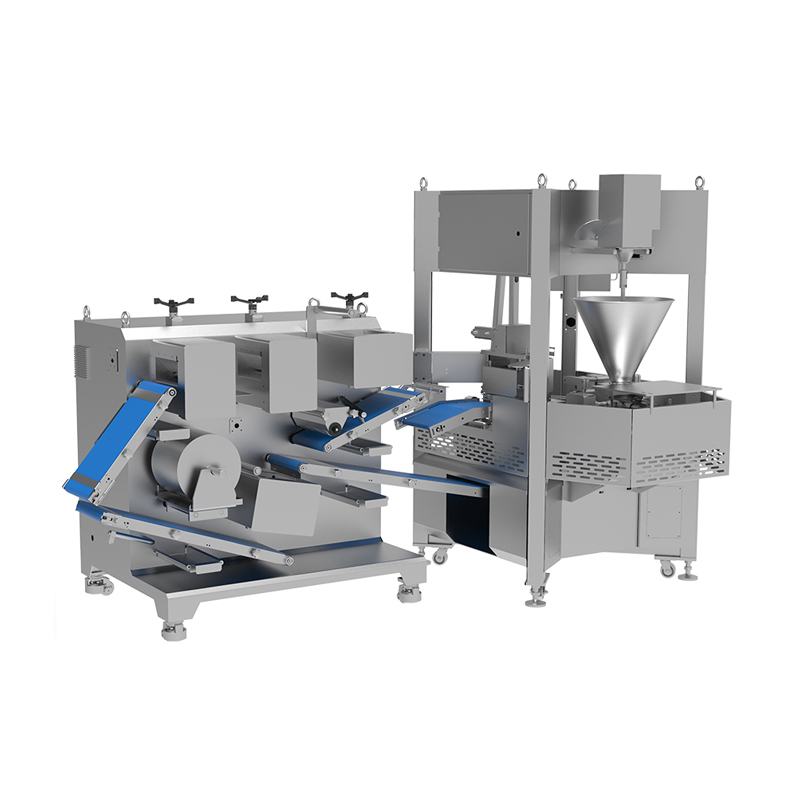

The Industrial Horizontal Mixer is primarily in the baking industry, including commercial bakeries, pastry shops, and large-scale food production facilities, such as bread, hamburgers, hot dog buns, cookies, crackers, pizzas, pie dough, and other snacks.

Showing Room